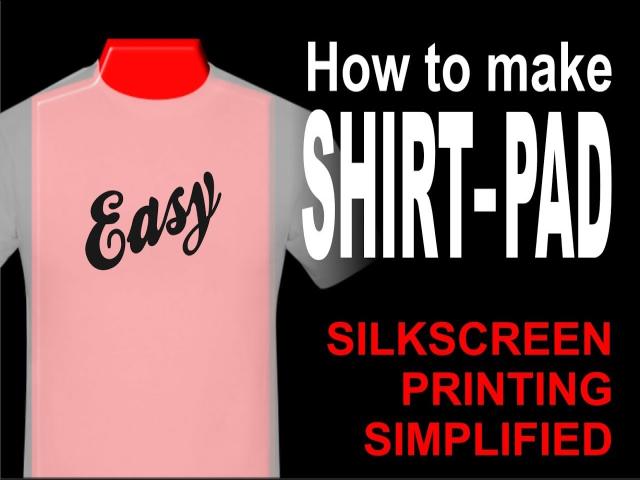

T-Shirt Screen Printing Made Easy

T-shirt screen printing, or 'Silkscreen printing as it is often called, has been around in some structures for quite a long time. The standard remaining parts are similar, from the more easy hand-printed method to enormous, completely automated presses. A negative picture of the artwork is singed onto a tight wreck stretched between a casing or 'screen.' The picture itself is misty. Ink is poured onto the cross-section, which is then constrained through the openings using a wiper that is either hand-drawn or automated. The misty negative picture won't permit ink to go through it. Thus, the positive imprint is then printed in printsrus onto the t shirt, which is put beneath the screen on a platen.

Creating custom t shirts is a tomfoolery project for your next family get-together or any event where you want to stand out from the group. Custom t shirts for the entire family will be considered a great keepsake gift and a token of the prime time everybody spent together.

There are a couple of things to remember while creating your custom t shirts for a family gathering. One is that a family crest or logo won't appear identical on the smallest kid or child's shirt as it will on triple XL Uncle Bob's t shirt. Pick a logo or size for the family crests to check different sizes. This can be effortless, assuming you pick a basic plan yet tell your family's story, and afterward have it measured to a medium print, and this way, it will fit everybody the equivalent.

Pick a bright shading for your family get-together custom t shirts if you meet in an enormous outdoor park or an amusement park; this way, everybody will want to see one another in the groups by just searching for peoples wearing similar t shirts.

A typical screen-printing setup can cost somewhere in the range of $8,000-$35,000—contingent upon the number of stations (platens) you use and the complexity of the press itself. A huge transport heater is expected to dry the t-shirts: an openness unit, a make-shift dim room, and a washing station to clean the screens.

T-shirt screen printing enjoys one distinct upper hand over other alternative methods accessible. It is fast. Between 30-90 t shirts an hour can be delivered from a basic 6 shading press. Ink costs are negligible too. In any case, since it is time-consuming to set up and clean the screens, most organizations charge the client a one-time setup expense for each shading separation. The screens are normally stored if the customer at any point needs to reprint.

The aces of screen-printing are an exceptionally spotless strong shading print. Great for logos and sharp text. Perfect for large-scale manufacturing and keeping the printing cost low on Printsrus print shop located in jacksonville fl. Excellent durability for washing and yet again washing often previously blurring. It will last more wash cycles than its counterparts like digital printing.

Cons of screen-printing: Not exactly suitable for photographic reproduction except if you have a lower grade of photo picture. Each tone must be printed separately; thus, a separate screen must be made and stored for each tone. Screen printing can be an untidy business to enter into.

If you are interested to see t-shirt screen printing in real life, a speedy hunt of YouTube will give many demonstrations by truly skilled experts.

Uniqueness And Facts of Onion Oil

- Put a little filling on each circle, wrap it up. Boil the dumplings for 8 minutes, and then fry for 2 minutes

How Can a Digital Marketing Agency Help You? What Is It?

- Do you manage a digital business, i.e., one that operates online and either sells goods

Kazakh president: Forces can shoot to kill to quell unrest

- Kazakhstan’s president authorized security forces on Friday to shoot to kill those participating in unrest, opening the door

Step by step instructions to Write Sales Emails That Get Best Responses

- With regards to deals messages, its one thing for a beneficiary to open them however something else altogether to respond to it.